CPL | How We’re Delivering Faster, More Reliable Builds for Our Customers

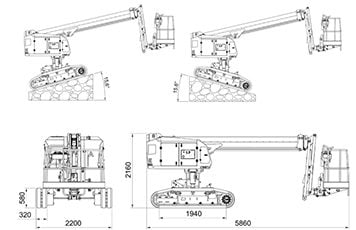

At CPL, our customers rely on us to deliver highly customised access platforms, on time, built right, and ready for work. As demand has grown, we’ve invested in smarter systems to make sure our production keeps pace without compromising quality.

By integrating our configurator, CRM, and production systems through DynamxMFG by Total Control Pro, we’ve created a fully connected build process that gives our team real-time visibility from order to delivery. That means fewer delays, clearer communication, and smoother handovers across engineering, kitting, and production.

“What used to rely on duplication and manual handovers now flows seamlessly from our configurator through to production. It’s helped us remove friction and deliver more consistently for our customers.”

— Philippos, Head of Digital Transformation

What this means for our customers

Faster lead times with fewer bottlenecks

More accurate builds thanks to connected engineering and BOM updates

Greater reliability, even on highly customised vehicles

Confidence that your platform will arrive when promised

Since implementing these systems, CPL has achieved

99.9% on-time delivery

75% reduction in manual admin

12% increase in production efficiency

For our customers, this translates into less waiting, fewer surprises, and a more dependable partner for critical access equipment.

We’re continuing to invest in technology that supports faster builds, better planning, and consistent quality, so you can focus on getting the job done, knowing your CPL platform will be ready when you need it.

👉 Read the full story from our systems partner to see how it works behind the scenes.

Explore our full product range | Check out the Configurator | Contact our team for assistance selecting your next MEWP.