Your Questions Answered

As an arborist, tree climbing is more than a job—it’s a lifestyle. You’re probably well aware of the incredible physical fitness required for this work, but have you considered the long-term effects it can have on your body? It’s no secret that working in the canopy, while rewarding, can take a toll over time if not managed properly. Let’s dive into our guide for Arborists and see what you need to know about keeping your body healthy for the long haul.

The Good:

Tree climbing offers impressive physical benefits. It demands upper body strength, core stability, and a high level of endurance. Climbing regularly keeps you fit, improves balance, and sharpens coordination. Many arborists report feeling in great physical shape, thanks to the intense physical activity involved in daily climbs.

Navigating branches and adjusting your position on the fly helps build incredible flexibility and balance, skills that come in handy both in and out of work. And don’t forget about the mental health benefits: working outside in nature and feeling a connection to the environment can reduce stress and boost your overall well-being

The Not-So-Good:

That said, the strain that tree climbing places on the body can lead to some serious long-term issues. Musculoskeletal injuries are common among arborists, particularly those related to repetitive motion and awkward postures. You might have already felt the aches in your shoulders, elbows, or knees after a long day of climbing—these are warning signs that overuse injuries like tendinitis or bursitis could be on the horizon

Moreover, arborists frequently report chronic back pain and even spinal problems, such as herniated discs, from the pressure of wearing harnesses and carrying heavy equipment. Over time, this wear and tear can lead to degenerative changes in the spine if not properly addressed

Grip and Hand Strength: A Hidden Challenge

One surprising discovery is the decrease in grip strength that can occur over time. You’d think all that gripping, pulling, and climbing would keep your hands strong, but many arborists experience a reduction in hand strength and even chronic issues like carpal tunnel syndrome. This often results from fatigue and the repetitive stress placed on the wrists and hands

The good news? Small changes, like using thicker ropes or ergonomic tools, can help reduce the strain on your hands and mitigate some of these issues

Respiratory Health: Don’t Ignore the Air You Breathe

Working in the canopy means frequent exposure to dust, pollen, and sometimes even chemicals like pesticides. Over time, this can lead to respiratory problems such as asthma or chronic bronchitis. You might not notice it right away, but long-term exposure to these elements can sneak up on you if you’re not careful

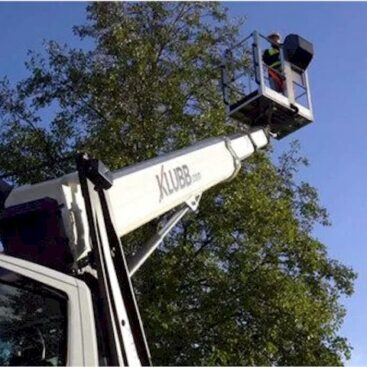

The vehicle mounted boom range produced by Klubb Group are intended for outdoor use. The use of this type of vehicle in strong winds or in gusty winds is regulated. In general, more than 45km/h is too windy to use our vehicle mounted boom units when the arm is expanded. However, some machines have an enhanced resistance and allow you to work at higher wind speeds. You will find this information in your product user manual and on the basket safety labels. Be careful not to forget to indicate these safety rules to your teams. Using safety devices properly enables operators to work productively and safely, not only for themselves but also for other.

It is the Beaufort scale that defines the speed and power of the winds. Invented in 1805 by Francis Beaufort, a British admiral, it goes from 0 to 12. The 0 corresponds to the absence of wind (less than 1 km/h), the 12 to a storm (more than 118 km/h). In between, there are different types of wind as breeze, fresh wind, gale.

However, the wind speed can be controlled quickly and precisely by using an anemometer. This meteorology instrument will instantly tell you the wind speed and pressure. It is an essential instrument used as the wind is one of the parameters which determine the evolution of the weather and the meteorological forecast. To analyze if it’s too windy to use our boom lifts, you will find the day prediction on many websites. You will find all the content you need to follow meteorological and climate live news and can follow up to 15 prediction days.

safety tips to follow when using a cherry picker

Working at heights can be a dangerous task if you do not follow the safety rule. There are many ways you can be serious injured, But, with the correct training you are able to drastically reduce those risks. Of course, using the right cherry picker is a pretty smart choice to conduct your intervention the safest way, but there are still some basic moves you can follow to further ensure your security.

In this regard, we would like to give you 4 tips for using a cherry picker to avoid the risk of injury or worse.

Check your environment

The first thing to do before getting into a cherry picker is to check the work area. Is the ground level or sloping? Is it degraded in places? Are there any particular obstacles that need to be avoided or that could potentially be dangerous for you and other road users? Even if you are working at height, it is essential, not to say vital, that you know the work area inside out in order to avoid possible risks.

Only make useful movements

A cherry picker has great mobility. Much more than any other type of lifting equipment. When working at height with such equipment, it is important not to make unnecessary or dangerous movements, such as leaning over to grab an object (a cut tree branch that does not want to fall, for example). In short, it is always better to maneuver a cherry picker to a specific area rather than to put yourself in unnecessary danger, even if you have all the safety equipment on you.

Curiosity is a dangerous flaw

One of the most underestimated dangers in our opinion is that of other road users, sometimes simply out of curiosity to see the aerial work platform in operation and will get too close to the work area. By doing this, they can put themselves and you in danger. The best advice we can give you is to mark out your intervention area with cones or barriers, to establish a safety perimeter so that no one can get too close.

Nothing better than good training

Any safety precaution will be pointless if the person using the equipment is unfamiliar with it. Working at height on a static tower or ladder is not the same as working on a moveable platform and so training should be given to all staff who use or may be called upon to use a cherry picker or any powered access platform.

The vehicle mounted boom range produced by Klubb Group are intended for outdoor use. The use of this type of vehicle in strong winds or in gusty winds is regulated. In general, more than 45km/h is too windy to use our vehicle mounted boom units when the arm is expanded. However, some machines have an enhanced resistance and allow you to work at higher wind speeds. You will find this information in your product user manual and on the basket safety labels. Be careful not to forget to indicate these safety rules to your teams. Using safety devices properly enables operators to work productively and safely, not only for themselves but also for other.

It is the Beaufort scale that defines the speed and power of the winds. Invented in 1805 by Francis Beaufort, a British admiral, it goes from 0 to 12. The 0 corresponds to the absence of wind (less than 1 km/h), the 12 to a storm (more than 118 km/h). In between, there are different types of wind as breeze, fresh wind, gale.

However, the wind speed can be controlled quickly and precisely by using an anemometer. This meteorology instrument will instantly tell you the wind speed and pressure. It is an essential instrument used as the wind is one of the parameters which determine the evolution of the weather and the meteorological forecast. To analyze if it’s too windy to use our boom lifts, you will find the day prediction on many websites. You will find all the content you need to follow meteorological and climate live news and can follow up to 15 prediction days.

Can you use a Cherry Picker on the highway?

Whether you work at height using a cherry picker often or not, you may drive the lift on the highway depending on the job that has to be done. But do not consider cherry pickers as common vehicles like cars or buses.

To go and place your cherry picker on the highway you need to respect some requirements. Here are the 8 most common conditions to follow in order to use a cherry picker on the main road. Yet for more information we recommend you to contact your local council.

1. A single operator is responsible for the proper application of the cherry picker’s uses. No decisions nor changes should be made without the approval of the operator.

2. Five working days’ notice of the planned work must be given in writing and sent to the local council of the town where you are to work. Verbal notice of 48 hours is also an option.

3. The duration of the work shall not be longer than the nature of the work requires. In this case, the competent authorities must be informed. They must also be notified if the work is to take place at night or on public holidays.

4. Council must have access, at any time, to the operation zone in order to control whether everything is going well or not.

5. The Council has the power to terminate the authorisation to use a cherry picker on the highway if necessary.

6. During the operations, the Applicant shall take all steps to ensure that the safety and well-being of the public is not jeopardised and shall comply with all reasonable requests made by the Council in this respect. (Attention is drawn to the publication Code of Practice 3010, 1972 – “Safe Use of Cranes”, available from the British Standards Institution of 2 Park Street, London, W1A 2BS).

7. If any damage is done to the highway as a result of the works, the person responsible for the operations shall pay the cost of any necessary repairs.

8. The operator responsible for the work at height has an obligation to take all necessary and preventive measures to ensure his safety and that of road users. In accordance with what is stated in Chapter 8 of the Road Signs Manual (Road Safety Measures and Signs for Road Works and Temporary Situations)

Are hard hats required on a cherry picker?

Although this is not mandatory, it is recommended to wear a hard hat on a cherry picker.

It’s an unstoppable logic, the higher you work, the more risk you take. Reason demands that you protect yourself from an accident, serious or fatal.

Besides, the Health & Safety Executive provides 2 smart advice’s when it comes to work at height, using a cherry picker or a ladder :

“where work at height cannot be easily avoided, prevent falls using either an existing place of work that is already safe or the right type of equipment”

“minimise the distance and consequences of a fall, by using the right type of equipment where the risk cannot be eliminated”

Source : https://www.hse.gov.uk/index.htm

Obviously the type of work will dictate the necessary hard hat PPE that has to be worn and consideration should be given to whether certain PPE is required or not and does introducing a particular piece of PPE introduce other risks.

There is a balance to be had with regards to wearing PPE that is necessary (as highlighted by the risk assessment) for the work being carried out and just wearing PPE for the sake of it (where the risk is low or minimal). Difficult to answer without further information, but the risk assessment should answer your question as to whether it is needed or not rather than is it a legal requirement.

As operators, you should consider wearing a safety harness, even if a guardrail system is sufficient. The harness won’t prevent a cherry picker fall, but it can limit the risk of an accident, injury, or fatality. Perhaps best of all, a harness can provide you with the peace of mind that you can work safely at heights.

Source : https://www.ipaf.org/en-us/resource-library/fall-protection-mewps-h1

Van cherry pickers are a common sight in many UK cities, often used for tasks such as building maintenance, and electrical work. However, with this equipment comes a level of risk, and it’s important for both operators and employers to be aware of the regulations that apply to van cherry pickers in the UK.

UK Regulations for van cherry pickers are primarily governed by the Health and Safety at Work Act 1974 and the Provision and Use of Work Equipment Regulations 1998 (PUWER).

Here are some key regulations to be aware of when operating a van with a cherry picker in the UK:

Safety Standards: Van cherry pickers must meet specific safety standards, such as the European standard EN280:2013. This standard covers the design and construction of van cherry pickers, as well as the requirements for stability, control systems, and emergency lowering devices.

Operator Requirements: There are specific requirements for van cherry picker operators. Operators must be properly trained and qualified, and must be able to demonstrate their ability to operate the equipment safely. Employers are also responsible for ensuring that their employees are not under the influence of drugs or alcohol while operating the equipment.

Inspections: Van cherry pickers are subject to regular inspections to ensure that they are in safe working condition. Employers are responsible for ensuring that their equipment is inspected and maintained in accordance with the manufacturer’s recommendations.

Weight and Size Restrictions: There are specific weight and size restrictions for van cherry pickers. It is important to ensure that the vehicle used to transport the cherry picker is suitable and capable of safely carrying the weight of the cherry picker and its load.

Insurance: There are specific insurance requirements for van cherry pickers. Employers are required to have liability insurance for their equipment, and operators should also have personal accident insurance.

Maintenance and Servicing: There are requirements for maintaining and servicing van cherry pickers. Employers are responsible for ensuring that their equipment is serviced and maintained in accordance with the manufacturer’s recommendations.

Public Space and Power Line Regulations: There are specific rules and regulations for using van cherry pickers in public spaces or near power lines. Operators must be aware of the rules and regulations and must take the necessary precautions to prevent accidents.

Driving and Parking Regulations: There are specific restrictions on where van cherry pickers can be driven or parked. Operators must be aware of these restrictions and must take the necessary precautions to prevent accidents.

Penalties for Non-Compliance: There are penalties for non-compliance with van cherry picker regulations. Employers can be fined or even face criminal charges if they fail to comply with the regulations.

In addition, there are regulations on the maximum working height of van cherry pickers, the need of specific license or certification to operate a van cherry picker, regulations on the training and qualifications of van cherry picker operators, the maximum load capacity of van cherry pickers, the use of personal protective equipment when using van cherry pickers, emergency procedures for van cherry pickers in case of breakdown or malfunction, the use of stabilising outriggers on van cherry pickers, emergency stop and emergency lowering device of van cherry pickers, and the noise emission of van cherry pickers.

It is important for both operators and employers to be aware of the regulations that apply to van cherry pickers in the UK. By following these regulations, employers can ensure that their equipment is safe and that their employees are properly trained and qualified. Ultimately, this will help to prevent accidents and ensure that van cherry pickers are used safely and responsibly.

For further information, you can contact us directly here, or take a look at the IPAF website which will give you detailed information on all of the areas discussed above.

Before loading your scissor lift onto a trailer, you need to first be aware of a few basic aspects.

Whatever experience you have, accidents happen and are almost always sudden. So it will never hurt to follow some sound advice

In this article – as you may have already guessed – we’re going to take you through the safest way to load a scissor lift onto a trailer.

The idea is not to tell you that you are doing it wrong, but to help you be as prepared as possible to load a scissor lift onto a trailer without risking injury to your employees or other road users. Safety is key

1 – Prevent any risk that could happened

When loading a scissor lift, you are responsible for making sure that everything is in working order. A risk assessment is a pre-emptive technique that allows you to sharpen up your fleet management processes and keep injury or risk of property damage to an absolute minimum.

2 – The importance of PPE

It is beneficial to wear PPE when loading a scissor lift. The basics are steel toe cap boots and a high viz jacket/ vest.

3 – Inspect your Trailer

What about the trailer? The third thing you should do is to carry out basic maintenance checks on your trailer. Make sure the trailer is within the service date, and the hauling capacity is suitable to load and support your scissor lift. The slightest mechanical defect could lead to a dangerous situation.

Loading your Scissor Lift onto a Trailer

Loading is simple so long as you tick every box before proceeding. Here’s what you need to do:

1 – Who is taking responsibility?

Its unlikely you will be loading your scissor lift alone. Furthermore, you should communicate with your colleague(s) so that you know who is responsible for what during the process.

2 – Clean your ramps

Cleaning your ramps of any mud or oil will prevent accidents due to the scissor lift slipping off or the equipment being held back by any uncleaned material

And of course, whilst on the subject of ramps, what condition are yours in? Which material do you use? Settling on the perfect loading ramps is essential for being able to load heavy machinery frequently and without issue.

3 – Clear your environment

Make sure if you always have room to manoeuvre as you wish. Especially for an operation like this which requires preparation and concentration. To avoid wasting time and once again injuring yourself, make sure that nothing is lying around.

4 – Line em’ up

Next up you’ll want to pilot the scissor lift and get everything lined up perfectly symmetrical with the loading ramps. As you are surely aware, approaching at an angle can be dangerous and cause the trailer to tip. Keep moving gradually using your spotter (or vice versa) to help you position the scissor lift perfectly for the loading procedure.

5 – Load your scissor lift onto the trailer

Once you are suitably lined up, you can slowly begin driving up the ramp. Remember that when on the ramp, the machine’s centre of gravity is going to shift; this is the most dangerous part of the process, so keep it moving steady and gradual until you make it over the crest.

Remember that when positioning your scissor lift on the trailer, to balance the weight towards the front of the trailer.

6 – Tie down your heavy equipment

Before moving the trailer anywhere, first you need to ensure that your scissor lift is thoroughly secured with ratchet straps that are in good condition.

You will probably have the opportunity to work at height using a scissor lift in the near future. While this type of lifting machine has many advantages, its main disadvantage is undoubtedly its transport.

Obviously, a scissor lift is less mobile than a truck-mounted lift, for example.

In some situations you will have to move your scissor lift from one location to another. In this article we explain how to transport a scissor lift safely.

Prepare the transport vehicle

If you are using a trailer and not a truck for transport, consider placing a nose jack under the front of the trailer. Adjust it so that it is two centimetres away from the trailer. This will prevent the trailer from tipping forward.

Loading the scissor lift

Your task now is to move the scissor lift onto the trailer or truck. This step is straight forward.

Securing the scissor lift

Even if the transport distance is short, it goes without saying that the scissor lift you are going to transport must not move. This could lead to a road accident. To properly wedge each wheel of the scissor lift, there is no better advice than to use wooden blocks. Wooden blocks that you will have to screw into the trailer.

Secure the machine

At this stage we recommend that you check that the fuel supply to the lift is switched off. If the machine runs on diesel or petrol, you must ensure that the fuel tank has been properly secured and that there is no risk of fuel escaping during transport.

You can never be too safe in terms of protection. So you can also disconnect the battery terminal. For two reasons:

- to reduce the risk of arcing

- to ensure that the engine does not start during transport.

Fixing the machine

Before you leave for your destination, you must ensure that the scissor lift is properly attached to the trailer. This can be done using chains, nylon straps and ties. These will be used to secure the machine to the edges of the trailer, to ensure that it will not move. Two chains or straps can be used to create four anchor points, one at each corner of the machine.

We hope that the instructions provided in this article have given you a good understanding of how best to transport a scissor lift. However, before undertaking any type of transport, it is important that you consult the instruction manual for the machine in question. The manufacturer may have included specific instructions on how to secure and transport their machines. If so, you should follow these instructions.

Before loading your scissor lift onto a trailer, you need to first be aware of a few basic aspects.

Whatever experience you have, accidents happen and are almost always sudden. So it will never hurt to follow some sound advice

In this article – as you may have already guessed – we’re going to take you through the safest way to load a scissor lift onto a trailer.

The idea is not to tell you that you are doing it wrong, but to help you be as prepared as possible to load a scissor lift onto a trailer without risking injury to your employees or other road users. Safety is key

1 – Prevent any risk that could happened

When loading a scissor lift, you are responsible for making sure that everything is in working order. A risk assessment is a pre-emptive technique that allows you to sharpen up your fleet management processes and keep injury or risk of property damage to an absolute minimum.

2 – The importance of PPE

It is beneficial to wear PPE when loading a scissor lift. The basics are steel toe cap boots and a high viz jacket/ vest.

3 – Inspect your Trailer

What about the trailer? The third thing you should do is to carry out basic maintenance checks on your trailer. Make sure the trailer is within the service date, and the hauling capacity is suitable to load and support your scissor lift. The slightest mechanical defect could lead to a dangerous situation.

Loading your Scissor Lift onto a Trailer

Loading is simple so long as you tick every box before proceeding. Here’s what you need to do:

1 – Who is taking responsibility?

Its unlikely you will be loading your scissor lift alone. Furthermore, you should communicate with your colleague(s) so that you know who is responsible for what during the process.

2 – Clean your ramps

Cleaning your ramps of any mud or oil will prevent accidents due to the scissor lift slipping off or the equipment being held back by any uncleaned material

And of course, whilst on the subject of ramps, what condition are yours in? Which material do you use? Settling on the perfect loading ramps is essential for being able to load heavy machinery frequently and without issue.

3 – Clear your environment

Make sure if you always have room to maneuver as you wish. Especially for an operation like this which requires preparation and concentration. To avoid wasting time and once again injuring yourself, make sure that nothing is lying around.

4 – Line em’ up

Next up you’ll want to pilot the scissor lift and get everything lined up perfectly symmetrical with the loading ramps. As you are surely aware, approaching at an angle can be dangerous and cause the trailer to tip. Keep moving gradually using your spotter (or vice versa) to help you position the scissor lift perfectly for the loading procedure.

5 – Load your scissor lift onto the trailer

Once you are suitably lined up, you can slowly begin driving up the ramp. Remember that when on the ramp, the machine’s centre of gravity is going to shift; this is the most dangerous part of the process, so keep it moving steady and gradual until you make it over the crest.

Remember that when positioning your scissor lift on the trailer, to balance the weight towards the front of the trailer.

6 – Tie down your heavy equipment

Before moving the trailer anywhere, first you need to ensure that your scissor lift is thoroughly secured with ratchet straps that are in good condition.

Klubb Group aerial work platforms are designed to ensure the safety of operators during work at height operations. However, it is important to specify that wearing a harness and lanyard is strongly recommended.

The most important thing is to prevent aerial platform operators falling from the boom lift.

To respect safety, wear a harness and lanyard when operating aerial work platforms . In the same way we recommend that you wear all PPE, personal protective equipment, to protect yourself. In general, the whole body can and should be protected during work at height in an aerial platform. We strongly encourage you to educate yourself and to thoroughly read the user’s Manual before using your aerial platform. Operators must be adequately trained, informed and have sufficient practice in using the machine safely.

To help you understand the equipment, we provide videos explaining all procedures you need to know to work in safe conditions (all the emergency operations, the control panel use…). To simplify the access to those videos we provide a QR code directly onto our aerial platforms, so you can rewatch them when you most need to.

According to the standards currently in force concerning protection against accidents, when on the platform the operator must:

– Wear a helmet or a bump cap.

– Wear and secure the specific lanyard belt to the ring attached to the basket:

Maximum authorised length of lanyard: 1 m

– The operator on the ground must also wear a helmet.

– Wear approved clothing protecting against accidents (non-slip safety shoes, jacket with reflective strips and gloves).

As IPAF, the international federation for equipment dedicated to work at height, reminds us, good compliance with safety rules significantly prevents the risk of falls. We invite you to consult their safety campaigns.

Aerial work platforms are used more and more for working at height. They reduce the risk of falls and provide significant comfort for a better quality of work. Cherry Picker Rental is ideal for businesses that do not want the full responsibility of the asset. It is important to define what type of rental corresponds to your use.

Unlike the short-term rental which meets specific needs with short periods of equipment use (less than 12 months). Long-term rental allows a company to rent a cherry picker for a set period (between 12 and 72 months) without managing its maintenance, servicing or repairs.

What are the advantages of this type of boom lift rental?

Long term rental

Ranging from 12 to 72 months, long-term rental allows equipment to be made available in return for a rent agreed in advance and with a fixed frequency. At the end of the commitment period, the lessee returns the equipment without the possibility of takeover.

A controlled budget

The budget is linear and controlled. The monthly cost is defined in advance. The risks associated with the use of the platform are transferred to the Rental company. The tenant pays a monthly payment based on the price of the equipment. A predefined mileage, associated services such as maintenance and insurance, or even fleet management, and the residual value. Everything is transparent and simple.

A retained investment capacity

Long-term rental allows you to optimise your fleet whether you are a Manager in a large company or in a medium-sized structure. It is fiscally advantageous because the rents are part of operating expenses and are therefore deductible. Long term rental contracts are therefore not included in your total cost of ownership (TCO). This cost represents all the costs of owning and operating a fleet, your borrowing capacity is also preserved.

Comfort and ease of use

This type of rental agreement also includes many services designed to make the daily life of the business owner easier. So servicing and maintenance, insurance, assistance in the event of a breakdown, changing vehicles if immobilised, replacing tyres are all subjects that can be included in your rental contract. It is all of these services that save you time and thus focus on your core business!

Technical responsiveness

Last but not least, a technical reactivity is included in your contract. Give preference to rental companies capable of helping you quickly with, for example, a telephone service available 7 days a week and 24 hours a day. Learn about the maintenance and repair of your equipment by studying the rental company’s fleet and its spare parts supply capacities. Quick repairs are your guarantee of continuous work.

In view of the various advantages of Cherry Picker Rental listed above, Long-term rental provides you with a machine without any constraints: a “turnkey” solution combined with optimal service.

For any inquiries, do not hesitate to contact our team. We work closely with a number of top rental companies int the UK to ensure they have versatile products and access to all parts needed to keep their fleets up and running.

Here we will answer the main questions asked to our technical support about Platform Operation.

How do I operate the E-motor?

At Lower Controls and basket controls, familiarise yourself with the E motor controls. Also look at the emergency procedures in the manual and scan the QR code on the dash to have a look at the training videos.

What is the P130 Emergency procedure?

Most people are not aware that there is a valve for the boom and a valve for the legs.

The easiest way is it to look at the user manual to familiarise yourself with the location of the override valves. Remove the control cage cover, this makes it easier to access to the valve at the rear of the spool controls.

In regards to using the hand pump. Use this rigorously to enable any movement of the boom. Once the boom is down repeat the procedure with the outriggers.

After any emergency procedures, call CPL to book a full check over and to reinstate the override clasps.

Van Mounts – What to do if the E motor is not working and stuck up in the air with no ground support.

In the event where no ground support is available, and the emergency motor is not working from the basket, the options are:

see if you can call from ground support.

Worse case scenario, emergency services will be the last port of call.

Below are some troubleshooting for the Pick up platforms and Van Mounts

Fault: Noisy PTO.

Advice: Refer to PTO Notice for ISUZU P130 Platform for full guidance.

Fault: Squealing PTO Belt or Pump Stalling.

Advice:

- Refer to PTO Notice for Isuzu P130 Platform for full guidance.

- If outside of this tolerance, CPL Attendance required to check condition of Pump, Tensioner & Belt.

Fault: Platform will not switch between Jacks & Booms.

Things to look for:

- Check condition of both of the Valves & Coils on the stabilizer control valve – are there any signs of wear or cracking? If so, these will need replacing.

- Check that the unstowed light is operating on each leg. Raise all legs and then unstow the first leg. Does the red light come on? If so, raise that leg and then unstop the second leg. Repeat this for each leg to check if the red light comes on. If it fails to come on with 1 or more of the legs, then either the switch is faulty or requires adjustment.

- Are all the green lights on when the legs are down and set? If not then they are not set correctly, or there is a faulty leg switch or it requires adjustment.

Fault: Outrigger Unstowed or Warning Reset Outrigger Red LED illuminated.

Things to look for:

- Outrigger may not be fully stowed – reset the Outriggers as per the Operators Manual.

- Is the boom not stowed up correctly?

- To stow the boom follow these Platform Operation guidelines:

Start Engine – Engage PTO – Screw in the Leg Override on the RHS of the Leg Controls – Deploy 4 Outriggers until Green LED is illuminated – Unscrew the Leg Override – Switch over to Lower Controls – Operate the Boom to stow correctly.

Fault: Loss of all Platform Functions.

Things to look for:

- Check that the Emergency Stop Switches are not pushed in. There are 2 on the Platform – 1 at the Deck Controls & 1 on the Basket Controls.

- Is the PTO Engaged? Check that the switch is pressed in & illuminated on the dashboard, then check in the Engine Bay to confirm that the belt is in place and PTO operational.

- Check the Plugs on the Loom to ensure there is no water ingress in to the plug – check for corrosion on the pins.

- Check the Fuses in the Deck Control Box – replace any if they have blown.

- Check the Circuit Board inside the Lower Control Box to ensure that there is no Water Ingress.

- Inspect Loom from Bulkhead (2 Glands) through Chassis to see if there are any wires that may have rubbed through and possibly earthing out. (This would need to be returned to CPL for repairs)

If none of the above work, the Operator will need to refer to the Operators Manual, Page 42 for Emergency Procedures.

Renault and CPL: a long term partnership based on successful conversions like the Renault Master aerial platform.

Our Renault Master aerial platform units are fully Type Approved and we are an approved converter.

A strong collaboration between CPL and Renault is the result of many years of collaboration. The Klubb Group have been Renault bodybuilder certified since the launch of this program by the French car manufacturer. The Klubb/CPL conversions such as the Renault Master aerial platform that come with this certification are guaranteed to be updated with all the latest innovations.

This long-term partnership has already proven its worth in the past. In the last 20 years, more than 10,000 aerial platforms have been mounted on a Renault Master and have been produced and distributed around the world. It’s not about to stop, in particular with the launch of the new Klubb/CPL KL range known as «light». This range includes Renault Master aerial platforms. These models are specially designed for sectors such as Telecoms, Public lighting, Utilities and Rental.

Among the models in this range, the KL32 on a Renault master is already considered as a European best-seller in the telecommunications sector. Its optimisation allows an additional payload of 140kg while maintaining the best technical performance on the market. This aerial lift mounted on a Master has a telescopic arm which reaches a working height of 12.30m and a horizontal offset of 6.90m, without outriggers. In addition, the KL32 Renault Master aerial platform benefits from a large loading capacity. This can transform the vehicle into a real mobile workshop if needed. It is then possible to work indoors, wherever you are.

Furthermore, your equipment is kept safely stored in your locked van.

The KL26 on a cutaway Renault Master, another model in the « light » range, is ideal for professionals requiring a minimum footprint. Its telescopic arm allows you to reach up to 11.80m height and 6.50m offset. It has been lightened to gain up to 160kg of payload. This model is very practical for all companies which need to transport equipment in order to intervene efficiently on sites. Even in areas that are difficult for parking or have restricted workspace.

To reduce your carbon footprint, it is possible to add the option of the Green Pack, available on each Klubb/ CPL model. This system allows the boom to work with the engine switched off. This option is ideal for all companies and local authorities engaged in an eco-responsible approach but do not wish to compromise on technical performance.

During the product design, Klubb, CPL and Renault worked together in order to design van mounts that are fully compliant with the new WLTP standard. This new European norm, Worldwide harmonized Light vehicle Test Procedure (WLTP), allows measurement of both fuel consumption and CO2 emitted by the vehicle. The CO2 emissions measured in WLTP are 24% to 31% higher than with the previous standard.

To meet international needs Klubb Group also design upper structure kits. The successful work with Renault is just one example. We are also working closely with many other car manufacturers such as Isuzu, Iveco, Ford, Toyota, Volkswagen and others…

Boom lifts are a safety machine allowing work at height, commonly referred to as a Mobile Elevating Work Platform (MEWP). The Klubb Group and CPL offers a large selection of models in order to fit with the requirements of many different sectors such as telecom, CCTV or street lighting installation and maintenance. These allow rapid interventions in places that may be difficult to access. Designed to safely accommodate one or more operators in their basket, the aerial platforms can replace traditional scaffolding or ladders and are a real time saver.

Despite their ease of use, it is necessary to follow several safety rules.

Here are the 10 safety precautions when using a boom lift which are important to know and respect.

Often carelessness, lack of vigilance or inadequate training can lead to accidents. It is therefore important to understand how the machine works and what to look for.

Train and verify the skills of its operators

The platform must be operated by people that have received training in the handling of aerial work platforms. Even if a safe driving aptitude certificate is not mandatory it is strongly recommended to have it before working at height. You will learn a lot about what to look out for when operating and working with cherry pickers.

Inspect the machine

It is essential to walk around the machine in order to detect any possible faults. Do not hesitate to use a checklist made available by the International Powered Access Federation (IPAF).

When vehicle leasing, it is also important to check that all documents for the vehicle and the platform are in your possession. These include, MOT, Loler and Service records and the manual.

Make sure the work area is secure

It is possible that the working environment presents more risks than the platform, pay attention to tree branches, electric cables, vehicles …. As you work outside, be especially vigilant to the power of the wind. Read Klubb’s article about it: When is it too windy to use a boom lift ?

Take care during work on public roads

It is essential to plan your work on public roads. As soon as you work in an urban environment, it is always important to ensure your safety but also be vigilant of others! Be visible! Manage traffic!.. are only basic examples, follow the IPAF advice.

Do not use a basket for handling or lifting too much weight

Aerial work platforms are only intended for lifting people and tools at height. They are not designed as handling equipment. They should therefore not be used as cranes to move objects or materials. The basket is fitted with a weight limit label. This should not be exceeded.

Respect the payload of your equipment

It is important not to overload the picker with equipment, excess people etc. The vehicle will be registered to a certain weight. If the access platform is overloaded it becomes unsafe. Police are cracking down on overloaded vehicles more and more. Consider purchasing a higher class MEWP, like the KL32 4.5t Cutaway, if you need the extra capacity.

Respect your equipment’s built-in safety devices

The safety devices integrated into your boom lift have been designed for your safety. The override functions should only be used in an emergency and can be found in the user manual or on the QR code videos.

Protect your whole body during work at height

We recommend that you wear full PPE, personal protective equipment, to protect yourself when operating or working near a MEWP. In general, the whole body can and should be protected during work at height in an aerial platform. The most basic requirements which are an absolute must are a well fitting harness, a lanyard and a hard hat or bump cap.

Your platform model must be suitable for the work you are carrying out

Your equipment should match with the work to be done, max. working height / max. lateral outreach / capacity / rotation…. For example if you need to work outside of the basket this is not the equipment you need. It can be overwhelming when you initially look at using an access platform for your work at height. Consult our team of specialists first. They will guide you through the options and suggest the best model for your work.

Do not ignore any of the above safety instructions

All the above precautions must be respected to ensure the upmost safety. Whatever the immediacy of your project, the most important thing is the safety of yourself and others around you!

Due to the heights that they can reach, accidents involving aerial work platforms can be very serious. Keep in mind that a good compliance with safety rules significantly prevents the risk of accidents.

We also advise you to stay up to date with the manufacturer’s safety information and user manuals. You will find many tips and recommendations in this FAQ (Frequently Asked Questions) section.

Do you need a license to operate a scissor lift?

In the UK, you do need a license for using a scissor lift. This is due to the potential risks when working at height using a scissor lift, for you and other road users.

The HSE States:

Training and certification

It is the employers responsibility to ensure that all MEWP operators have been adequately trained.

Although specific courses are not a strict legal requirement, there are recognised schemes available. Once the training and assessment has been successfully completed, the operator is given a training certificate or card, which clearly identifies the operator and lists the categories of MEWP they are trained to operate. This document can be updated as the operator undergoes further training on different types/ sizes of MEWP. You should check the expiry date of the training certificate or card.

As an operator it is good practice to be trained to operate aerial platforms like scissor lifts. We recommend you book an IPAF registered training course, in which you will learn all risks and requirements and safe use of aerial platforms.

The internationally recognised IPAF training course is in place to provide delegates with an understanding of the need for accident prevention, safe operational procedures, emergency descent operations and gives an overview of the responsibilities of employers and employees. The IPAF course will also cover the main aims of the Health & Safety at Work Act 1974 and associated regulations.

As a result of this training, IPAF will give you a license which will certify your capacity to use a scissor lift.

Due to their efficiency and safety, a scissor lift can be used for numerous applications requiring work at height. In this article we will outline with you what work requires the use of scissor lifts.

Scissor lifts for Building Maintenance

Building maintenance includes many jobs that require working at height. Replacing lighting, hanging advertising banners, laying or replacing bricks are just a few examples of applications in building maintenance. With scissor lifts, operators can work both indoors and outdoors to complete their tasks in complete safety.

Scissor lifts for Construction

Scissor lifts provide a versatile solution for construction projects that may have frequently changing environments. The Almac range has a self levelling system allowing the platform to move across rough and uneven terrain.

Scissor lifts for Warehousing

When storage is the name of the game, every vertical and horizontal inch of space must be used efficiently. Investing in a scissor lift for warehouses can open new areas for use or expedite the retrieval process.

Scissor lifts for Overhead signs

The world is full of signs that often need changing. From individual establishments to property manager multiple sites, rental or ownership of a scissor lift can alleviate many worries and headaches associated with making those changes.

Scissor Lifts for Decorating

Whether indoor or outdoor, a scissor lift is a safe and efficient way to access all areas. There is room within the basket to hold all materials and the cage can extend removing the need to constantly move the entire unit. Compared to a ladder, this solution is safer, will take less time and it is less likely that there will be a spillage or splattering of paint.

What is noise pollution from a work platform?

Noise has emerged as a leading environmental nuisance in the World Health Organization (WHO) European Region, and the public complaints about excessive noise more and more often. Irritating noise can come from all kinds of sources: air conditioning, loud music, traffic, nearby construction…

How to measure noise pollution?

50 or 55 dB represent daytime levels below which a majority of the adult population will be protected from becoming moderately annoyed, respectively. The WHO defines noise above 65 decibels (dB) as noise pollution. To be precise, noise can becomes harmful when it exceeds 75 decibels (dB) and is dangerous above 120 dB. Traffic noise accounts for most polluting noise in cities. For example, a car horn produces 90 dB and a bus produces 100 dB.

What are the causes of noise pollution when working at heights?

When working at heights, the use of an aerial platform on a vehicle is one of the sources of noise. The maximum noise level measured during the use of the MEWP is 90dB.

Most of the noise in coming from the diesel engine of the vehicle. If necessary, do not hesitate to wear suitable ear defenders.

How do you prevent noise pollution when using an aerial platform to work at height?

– Good maintenance

First, a machine that is not properly maintained can generate more noise than usual. In order to avoid this, make sure your aerial platform is properly serviced as many times in the year as your local regulations require.

– Do not overload the basket

Overloading the MEWP is dangerous and can also cause an increase of noise when using the lift. The lifting capacity of the MEWP corresponds to the service load for which it was designed and includes the weight of the operators and tools needed for the specified activities. Always ensure that you respect the loading capacity of the lift you are using. To know more, check our article: What are safety precautions when using boom lifts?

– Choose the right lift

In order to reduce noise pollution and pollutant emissions, Klubb has designed a range of eco-responsible platforms on vehicles which are accessible through CPL.

100% electric platform on vehicle

The work platform does not release pollutants into the atmosphere when working at height. They are also almost silent, which is a real plus for operators working at night and residents.

The 100% electric models are perfect for working in the city, especially in pedestrian areas or on industrial sites.

Electric lifting platforms on vehicles: the hybrid option

If the previous option is not suitable for your work at height, you can still equip yourself with an electrically operated aerial work platform on a diesel vehicle.

Of course, the vehicle remains noisy during trips, but you can work at height with the vehicle’s engine off. This makes it possible to limit noise pollution.

This option applies to all types of Klubb Group vehicle mounts: Vans, light trucks or heavy trucks.